A Process For Execution Management

I can remember early in my career when I was asked to manage

a department that was disorganized and not meeting its organizational

objectives. While somewhat flattered, I was also afraid that I wouldn’t be

successful. I didn’t have experience in defining organizational problems or

developing their solutions. In this particular case I just decided to take an

action and see where it led. As luck would have it the early actions raised

questions that would require that I do some research into how others had dealt

with similar problems.

In most cases the research gave good pointers on how to move

forward and what next steps might produce results. The next steps usually led to

more questions that required further research which led to still more steps to

be taken.

While this approach moved the project forward, it didn’t

provide a list of activities that would focus on improving the department’s

ability to function effectively. This approach almost required that I discover

problems and inconsistencies as I tried to implement changes.

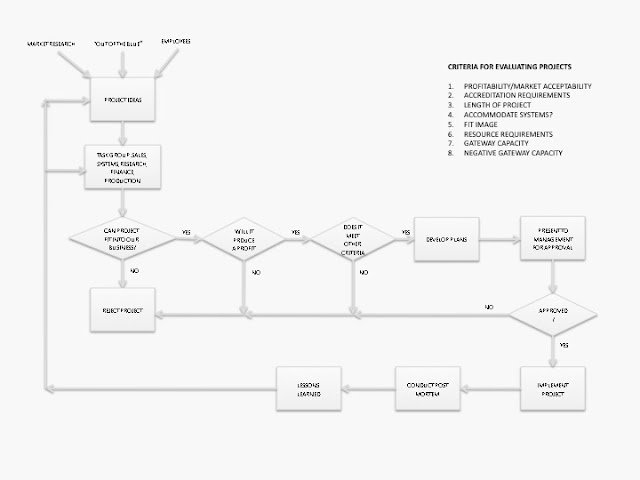

As in the above situation, there are established businesses that must make

changes in their organizations to grow or even to survive. There are also a lot of great ideas for new business initiatives and new businesses. In either case the difference

between a needed outcome and achieving that outcome is in execution.

Execution is the process of taking something from an idea to

a completed project. The ability to successfully execute a project usually boils down to attention to details. It

requires breaking a needed outcome into components that can be described and

measured.

I have been very fortunate to be given the opportunity to

work on a myriad of projects for existing and new organizations. Over time this

led to bigger projects and ultimately to starting and operating new business

ventures. With each of these projects there came a deeper understanding of how

best to define actions to take in order to have a successful project. I found

that the best process started with a clear definition of the needed outcome.

Once the outcome was defined, a review of all of the steps needed to achieve

that outcome helped identify actions that were needed. This allowed the development of an

execution plan rather than discovering needed actions during an implementation

effort.

If the components of a project’s envisioned outcome are

specific enough then a plan can be developed. The plan must be specific and

detailed enough to completely implement the envisioned initiative.

The plan must consider all aspects of an initiative:

environment, economy, competition, resources required, coordination of

marketing strategy with management capabilities and so on.

Here are some steps using an end-to-beginning planning

process to improve the level of execution success.

Planning – When

setting a plan, envision the end result then take this vision and begin working

backward to the beginning of the project. If the vision is to open a retail

outlet, envision the store, the customers, the location, the merchandise, the

fixtures and layout, your income (or profit), the employees and their level of

expertise and so on.

Each of these envisioned characteristics require specific

actions. For example, if an upscale location is envisioned then identifying

acceptable sites, rents, build-out requirements and lease terms are required

action items.

Envisioned profit levels will require a certain sales

volume, pricing strategy and marketing effort. The staffing quality will come

at a certain level of payroll and benefit expense. The actions here will help

in developing the strategy for the initiative.

List of action items

– The action items for each characteristic should be listed in a sequential

format. For example one would need to identify a location before considering

build out requirements. The sequence of action items once laid out should be

set to a specific timetable. Thus if opening a retail outlet is envisioned to

take place in six months, the identification of an acceptable outlet would have

to take place and leave enough time to negotiate lease terms, build out,

installing fixtures and inventory.

At his stage the planner may find that there are conflicts

that require resolution. In this example if the build out requires four months

and fixtures have a five-month lead-time, adjustments will have to be made in

the time line. It may require setting a different opening date or finding ways

to order fixtures before build out activities begin. This is where the use of a

Critical Path or PERT chart would be useful. Mind Tools provides a good tutorial for using CPM and PERT at

http://www.mindtools.com/critpath.html.

There may also be strategic conflicts. For example if the

end-to-beginning analysis uncovers competitive, legal or other potential

roadblocks additional strategic planning may be required.

Assign specific

action items and timetables to individual managers - This allows each

activity to be tracked by a responsible individual. This individual can alert others

when difficulties are encountered so actions can be taken to keep the whole

project on schedule.

This approach allows the identification of the final

objective and a means of analyzing all aspects of the project in the planning

stage rather than in the execution stage. It also helps uncover inconsistencies

in strategic planning.

Once the vision is consistent with the actions necessary for

implementation then the activities are arranged in the most efficient sequence

and assigned to responsible individuals for follow through. This approach significantly increases to chances that the execution of a project will be successful.

Comments